Help is also available from our technical support staff

Frequently Asked Questions

Here’s where you will find answers to commonly asked questions about choosing, upgrading and using Ra Workshop software. If you need more information before making your purchase decision, don’t hesitate to contact us.

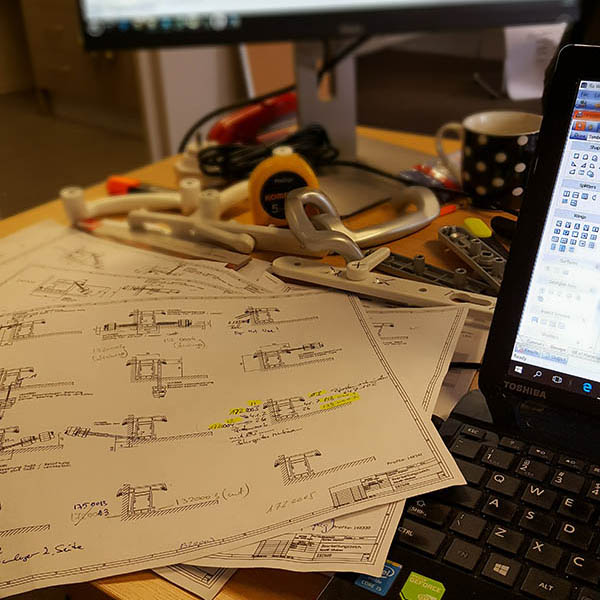

RA Workshop can compute any profile system for windows and doors: PVC, AL and Wood. Also, it can work out with any hardware system even if it’s an international brand or a local one. Finally, you glass list will be up and running so you can have an accurate bill of material when calculating project.

RA Workshop, depending on the edition that you have can design and calculate a complete range of openings: casements, awnings, tilt and turns. French windows, sliding, lift and slide, bifold, tilt and slide, pivots, insect screens, shutters, etc. Our more than 15 years’ experience, working with customers all over the world, made us believe, there are not windows or doors that we can’t compute.

Depending on how many profiles and hardware systems you are using, our support team is able to estimate the number of hours needed to fully your database setup. It is usually taking between 2 to 4 weeks from gathering the information from you or from your supplier until you can start using RA Workshop in production. Take into consideration that changes to the database may appear along the way as you will finetune your products and we can anytime help you with these changes as we are offering after delivery support to our customers.

We have a support department that is in charge with trainings and any request that may come from the customers. We are supporting you via email, phone, skype or remotely connecting to your computer via TeamViewer. Also, if requested, we can send a team on site, in your showroom or factory to train and support you employees to better perform when using RA Workshop.

One of our biggest challenge is to support our customers all over the world. That’s why, people in our support department are working in shifts to assists projects in North and South America as well as Australia and New Zeeland.

The database setup features is open, so whatever our support team is doing in the database, you or your team as a customer can do as well. The disadvantage of managing RA Workshop database yourself is that involved more time from your team, but the big advantage will be that you will have a good knowledge of how the software is working in the background. It is up to you to take the decision to let RA Workshop team manage the database or do it yourself.

You can download anytime RA Workshop Trail version. It is a fully, functional estimation and production version that will work for 30 days. You can check and test any features of our software and verify it is the proper solution for you company.